Welcome to Jiangsu Yigao Medical

Welcome to Jiangsu Yigao Medical

E-MAIL:[email protected]

E-MAIL:[email protected]

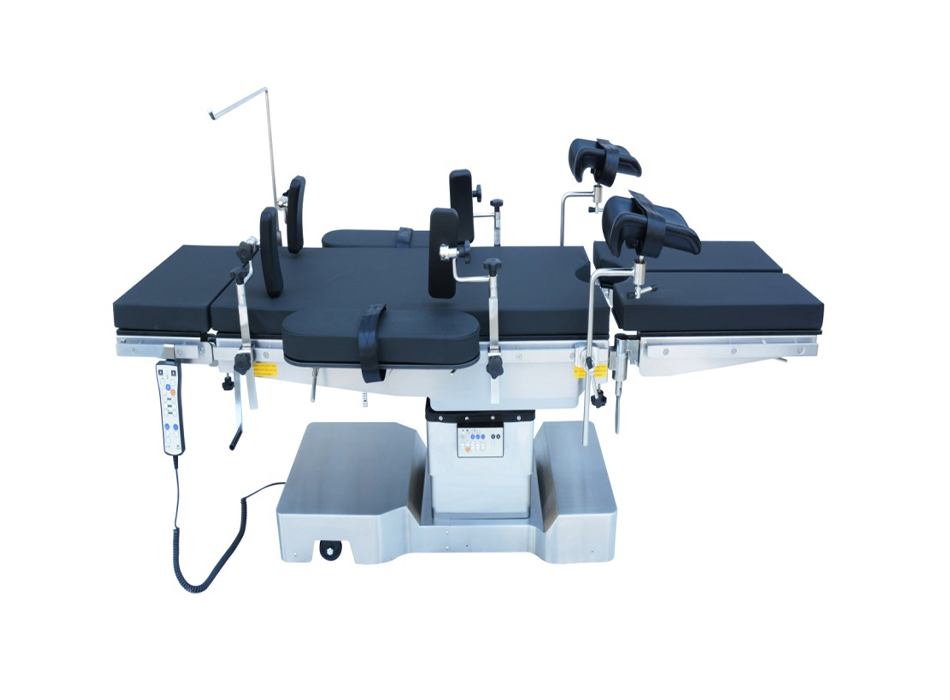

Electro-hydraulic operation tables, often referred to as surgical or operating tables, are advanced pieces of medical equipment used in modern operating rooms. They provide a stable and adjustable platform for positioning patients during various surgical procedures. Unlike their manual or purely electric counterparts, these tables combine the power of an electric motor with the smooth, controlled movement of a hydraulic system. This hybrid design offers the best of both worlds: the effortless adjustability of electric controls and the robust, precise lifting and tilting capabilities of hydraulics.

The basic function of an electro-hydraulic operation table is to safely and securely position a patient in the optimal orientation for a specific surgical procedure. This can involve a wide range of movements, including raising, lowering, tilting from side to side, and adjusting the trendelenburg and reverse-trendelenburg positions. These adjustments are crucial for providing surgeons with clear access to the surgical site, improving visibility, and enhancing procedural efficiency and safety.

The key components of an electro-hydraulic operation table work in harmony to achieve this functionality. The hydraulic system is the core of the table's power. It consists of a reservoir of hydraulic fluid, a pump, and a series of cylinders that translate the fluid pressure into mechanical motion. The electric controls are the brain of the system, comprising a motor, control unit, and various user interfaces like a handheld remote or a foot pedal. These controls allow the surgical staff to precisely and effortlessly manipulate the hydraulic system. The tabletop is the surface where the patient lies. It is often made from a radiolucent material, allowing for clear X-ray and fluoroscopic imaging during surgery without the need to move the patient. Finally, the base provides stability and mobility, typically featuring heavy-duty castors for easy transport and a braking system to lock the table securely in place during a procedure. Together, these components create a sophisticated, reliable, and essential tool for modern surgical practice.

Electro-hydraulic operation tables represent a significant advancement over traditional manual or purely electric surgical tables, offering a suite of benefits that enhance surgical outcomes, patient safety, and operational efficiency. The integration of electric power with a hydraulic system provides a level of control, stability, and versatility that is indispensable in today's demanding surgical environment.

One of the most critical advantages of electro-hydraulic tables is the unparalleled precision and control they offer. The hydraulic system allows for smooth, incremental adjustments, preventing the jarring movements that can occur with purely manual systems. Surgeons can fine-tune the patient's position to the exact angle and height required for optimal access to the surgical site. This level of accuracy is particularly vital in delicate procedures such as neurosurgery, ophthalmology, and microsurgery, where even a slight tremor in the table's movement could compromise the outcome. The electric controls, typically managed through a handheld remote or a foot pedal, provide intuitive and instantaneous command over all table functions, allowing the surgical team to make adjustments without breaking their sterile field or disrupting the flow of the procedure.

Patient safety is paramount in any surgical setting, and electro-hydraulic tables contribute significantly to this goal. The robust hydraulic system ensures that the table remains stable and secure, even when supporting heavy patients or during dynamic movements. The automatic locking mechanisms and emergency stop functions provide an additional layer of security, preventing accidental movements or shifts during critical moments of the surgery. Many tables also feature safety sensors that prevent collision with other operating room equipment. Furthermore, the smooth, controlled movements of the table minimize the risk of patient discomfort or injury during positioning and repositioning. The ability to achieve a wide range of positions, including Trendelenburg, reverse Trendelenburg, and lateral tilts, without manual effort reduces the physical strain on the patient and staff, ensuring a safe and secure environment throughout the operation.

Time is a critical factor in the operating room. Electro-hydraulic tables dramatically improve efficiency by enabling quick and effortless adjustments. Unlike manual tables that require physical exertion and can be cumbersome to operate, these advanced tables can be positioned with the push of a button. This speed allows the surgical team to react swiftly to the needs of the procedure, whether it's for better exposure, patient comfort, or to accommodate the requirements of a specific surgical instrument. The efficiency gained not only reduces the overall time of the surgery but also contributes to a smoother workflow, allowing the team to focus on the procedure itself rather than the logistics of patient positioning.

The physical demands on surgical staff, particularly during long and complex procedures, can be immense. Electro-hydraulic tables are a major boon to ergonomics. By eliminating the need for manual cranking, lifting, or pulling, these tables significantly reduce the physical strain on nurses, surgeons, and anesthesiologists. The ability to easily adjust the table's height and orientation ensures that the surgical team can maintain a comfortable and neutral posture, preventing repetitive strain injuries and long-term musculoskeletal problems. This enhanced ergonomic design not only improves the well-being of the staff but also contributes to better focus and performance throughout the surgery.

The versatility of electro-hydraulic tables makes them a cornerstone of any modern operating room. While general surgery tables are designed for a broad range of procedures, many are modular and can be easily configured with specialized attachments. This adaptability allows a single table to be used for multiple specialties, including orthopedic surgery, neurosurgery, bariatric surgery, urology, and cardiac surgery. For example, a general surgery table can be fitted with a traction device for orthopedic procedures or a headrest for neurosurgery. This modularity not only makes the tables highly cost-effective but also allows hospitals to optimize their equipment usage and reduce the need for multiple, single-purpose tables. The ability to perform a wide variety of procedures on a single platform streamlines the operating room's logistics and inventory management, making it a truly versatile asset.

When selecting an electro-hydraulic operation table, a thorough evaluation of its features is crucial to ensure it meets the specific needs of a surgical facility. The right table can significantly enhance surgical outcomes, improve patient safety, and streamline the workflow of the operating room. Here are the key features to look for when making this important investment.

The weight capacity of an operation table is a primary consideration. With the rising global rates of obesity, modern surgical tables must be able to safely accommodate a wide range of patient sizes, including bariatric patients. A table with a higher weight capacity provides greater versatility and ensures that the facility is prepared for various patient demographics. Look for a table that not only specifies its maximum patient weight but also its dynamic weight capacity, which accounts for the forces exerted on the table during movement and surgical procedures. A robust weight capacity is non-negotiable for patient safety and is a key indicator of the table's overall structural integrity.

The material of the tabletop is another critical feature, particularly in procedures that require intraoperative imaging. A high-quality tabletop should be made from a radiolucent material, such as carbon fiber or a specific composite. This allows for clear, unobstructed X-ray and fluoroscopic imaging without the need to move the patient, which could disrupt the sterile field or the surgical procedure. Some tables offer a full-length radiolucent area, which is essential for spine and orthopedic surgeries. The material should also be durable, easy to clean, and resistant to stains and disinfectants to maintain a sterile environment.

The level of adjustability is a defining characteristic of an excellent surgical table. Look for a table that offers a broad range of motion in all planes. Key adjustments include:

Height: A wide height range allows the surgical team to position the patient at an optimal level for both standing and seated procedures. This feature is vital for the ergonomics of the surgical staff.

Tilt: Lateral tilt, or the ability to tilt the table from side to side, is crucial for improving surgical access and drainage. The degree of tilt should be significant enough to provide a clear view of the surgical site.

Trendelenburg and Reverse Trendelenburg: These movements, which involve tilting the table with the head down or head up, are essential for managing blood flow and for specific surgical approaches, particularly in abdominal and pelvic surgeries.

Rotation: The ability to rotate the tabletop or the entire table on its base provides exceptional flexibility, allowing the surgical team to reposition the patient without a full physical transfer.

Leg and Back Section Adjustments: Look for tables with modular sections that can be raised, lowered, or removed to accommodate various patient positions and surgical needs. This feature is particularly useful for specialty procedures.

A user-friendly and reliable control system is fundamental to the table's functionality. Most electro-hydraulic tables come with a handheld remote control that allows for precise, fingertip control of all table movements. A good remote should be intuitive, with clearly marked buttons and a waterproof or sealed design to withstand the operating room environment. Foot pedals are another valuable control option, as they allow the surgeon to make adjustments without using their hands, maintaining sterility. Some advanced tables feature integrated control panels on the base of the table or even wireless controls, offering redundancy and flexibility.

Safety should always be a top priority. Essential safety features to look for include:

Emergency Stop: An easily accessible emergency stop button that immediately halts all table movements in case of an unforeseen event.

Locking Systems: Robust locking mechanisms on the castors and base prevent any unintentional movement of the table during surgery.

Collision Sensors: Some high-end tables are equipped with sensors that can detect and prevent collisions with other operating room equipment.

Manual Override: A manual override or a built-in battery backup system is crucial for ensuring the table can be safely returned to a level position in the event of a power failure.

Finally, consider the table's mobility and stability. The table should have high-quality castors that allow for smooth and easy transport, even across uneven floors. The braking system should be reliable and secure, ensuring that once the table is in place, it remains absolutely stable throughout the procedure. Some tables feature a central braking system that locks all castors simultaneously, providing maximum stability. The base design should be low-profile to allow for easy access for surgical teams and imaging equipment, while also providing a wide footprint for excellent stability.

The world of electro-hydraulic operation tables is not a one-size-fits-all domain. Manufacturers have developed specialized tables to meet the unique demands of different surgical disciplines. While they all share the core electro-hydraulic technology, their design and features are tailored to optimize specific procedures. Understanding the various types is crucial for a hospital or clinic to select the right equipment for its surgical needs.

General surgery tables are the workhorses of the operating room. Designed for maximum versatility, they are a fundamental piece of equipment in any hospital. These tables are built to handle a broad spectrum of surgical procedures, from appendectomies and hernia repairs to laparoscopic surgeries. Their key characteristic is a modular design that can be easily adapted with various attachments. For instance, a general surgery table can be converted for use in gynecology with leg supports or fitted with armboards for certain upper body procedures. They typically feature a wide range of height, tilt, and rotational movements, making them suitable for accommodating different patient positions and surgical approaches. Their robust construction and high weight capacity also allow them to serve as a reliable platform for a wide array of patients and operations, making them a cost-effective and essential asset for multi-specialty surgical centers.

While general tables are versatile, specialty tables are engineered with a single purpose in mind: to excel in a particular surgical discipline. These tables offer features and accessories that are specifically tailored to the unique requirements of complex surgeries.

Orthopedic Tables: These tables are designed for bone and joint surgery, particularly for procedures involving the spine, hips, knees, and extremities. A key feature is the inclusion of traction devices, which can be used to stretch and manipulate limbs, providing surgeons with better access and alignment. They often have a radiolucent design and a "floating" tabletop to facilitate C-arm fluoroscopy and advanced imaging during complex orthopedic procedures.

Neurosurgery Tables: Neurosurgical tables are built for precision and stability. They typically include specialized headrests and cranial stabilization systems to securely hold the patient's head during delicate brain and spinal surgeries. Their design often allows for extreme positioning to provide the surgeon with an optimal line of sight and access to the surgical field, which is critical in neurosurgery.

Cardiac and Vascular Tables: These tables are designed to support complex cardiovascular procedures. They often feature a longer tabletop to accommodate the full length of the patient, and their design allows for excellent fluoroscopic imaging, which is essential for procedures like stent placements and bypass surgeries. Some models may have features to facilitate specific heart-lung machine setups and patient monitoring.

Bariatric surgery tables are a crucial category of specialty tables, specifically designed to address the needs of obese patients. The primary feature of these tables is their exceptionally high weight capacity, often exceeding 1000 pounds. They are built with reinforced frames and robust hydraulic systems to ensure patient safety and table stability during complex bariatric procedures. The tabletops are wider and often longer to comfortably and securely accommodate larger patients. Furthermore, bariatric tables are designed with extra-wide lateral tilt capabilities to assist in patient positioning and to provide the surgeon with better access to deep surgical sites. The investment in a bariatric table is a critical component of a hospital's commitment to patient safety and its ability to serve a growing segment of the patient population.

Mobile electro-hydraulic tables, while less common than their fixed-base counterparts, serve a vital purpose in specific medical settings. These tables are designed for portability and quick setup, making them ideal for use in field hospitals, emergency response situations, or smaller clinics with limited space. They are typically lighter and more compact, often featuring a power supply that can run on a battery for a limited period. While they may not offer the same extensive range of features and weight capacity as a full-size table, their ability to be easily transported and deployed makes them invaluable in situations where a fixed operating room is not available. They provide a reliable and safe surgical platform in non-traditional or temporary settings, ensuring that critical care can be delivered wherever it is needed.

Selecting the right electro-hydraulic operation table is a significant decision for any hospital, surgical center, or clinic. It's a long-term investment that directly impacts surgical outcomes, patient safety, and staff efficiency. Beyond the basic features, several key factors must be carefully evaluated to ensure the table is the perfect fit for the facility's specific needs.

The budget is often the first and most practical consideration. Electro-hydraulic tables vary widely in price, from entry-level models to high-end, multi-specialty systems. It is crucial to determine a realistic budget that balances initial acquisition costs with the long-term value of the equipment. While it might be tempting to opt for the cheapest option, it’s important to remember that a table with a more robust set of features, higher weight capacity, and greater durability may save money in the long run by reducing the need for multiple tables and minimizing maintenance costs. Conversely, purchasing a table with advanced features that will not be used may be an unnecessary expense. The goal is to find the sweet spot where the table’s capabilities align perfectly with the facility's surgical needs and financial constraints.

The most important factor is the type of surgeries the table will be used for. A general surgery center will have different requirements than a specialized orthopedic or neurosurgery hospital.

General Surgery: If the facility performs a wide range of procedures, a versatile, modular table is the ideal choice. Look for a model that can be easily configured with various attachments for different surgeries, such as gynecology, urology, or general laparoscopic procedures.

Specialty Surgery: For facilities that focus on a specific discipline, a dedicated specialty table may be a better investment. For instance, an orthopedic clinic should prioritize a table with traction capabilities and excellent radiolucency. A hospital with a significant number of bariatric patients must invest in a high-weight capacity bariatric table to ensure patient safety and staff comfort.

Future Growth: Consider the facility’s long-term plans. If there is a potential to expand into new surgical specialties in the future, a modular and adaptable table will provide the necessary flexibility without requiring a new purchase down the line.

The physical dimensions of the operating room play a crucial role in table selection. A large, complex table might be a perfect fit for a spacious operating theater but could be cumbersome and difficult to maneuver in a smaller room. Consider the table’s footprint, especially its base design. A low-profile, compact base can provide more legroom for the surgical team and allow better access for imaging equipment like C-arms. The mobility of the table is also key. High-quality castors and an effective braking system are essential for smooth repositioning within the operating room and secure placement during surgery.

A surgical table is a complex piece of machinery that requires regular maintenance to ensure its reliability and safety. Before making a purchase, thoroughly research the manufacturer's reputation for after-sales service and support. Ask about the availability of local service technicians, the typical response time for repairs, and the cost and lead time for spare parts. A table from a reputable manufacturer with a strong service network will minimize downtime and ensure that the equipment is always in optimal working condition. Consider the ease of performing routine maintenance checks, such as hydraulic fluid levels and electrical safety inspections.

An advanced table with all the bells and whistles is only as good as the staff's ability to use it effectively. The control system should be intuitive and easy to learn. Handheld remotes with clear, logical button layouts and foot pedals that are simple to operate are key. Manufacturers should offer comprehensive training for the surgical team to ensure they are comfortable and proficient with all the table's functions. A table that is difficult to operate could lead to procedural delays and potential safety risks. Prior to purchase, it is advisable to get a demonstration of the table to assess its user-friendliness and to solicit feedback from the surgical staff who will be using it daily.

Proper maintenance and care are essential for ensuring the longevity, reliability, and safety of an electro-hydraulic operation table. As a critical piece of medical equipment, a well-maintained table not only protects the significant investment but also, more importantly, guarantees patient safety and procedural efficiency. A proactive approach to maintenance, encompassing regular cleaning, system checks, and safety inspections, is crucial to prevent operational failures and potential hazards.

The operating room is a sterile environment, and the surgical table is at the heart of it. Regular and thorough cleaning is the most fundamental aspect of maintenance. The table should be cleaned and disinfected after every single use to prevent the spread of infections.

Daily Cleaning Protocol: The entire surface of the table, including the tabletop, mattress, base, and castors, should be wiped down with hospital-grade disinfectants. It's crucial to follow the manufacturer's guidelines for compatible cleaning agents to avoid damaging the table's surfaces or materials. Special attention should be given to crevices and joints where fluids or contaminants can accumulate.

Preventing Contamination: The control units, such as handheld remotes and foot pedals, should also be disinfected regularly, as they are frequently touched during procedures. Using sterile covers for these controls can further enhance hygiene and simplify cleaning.

Mattress Care: The patient mattress, often made of a radiolucent and fluid-resistant material, should be inspected for tears or punctures. Any damage must be addressed immediately, as it can compromise the fluid-resistant barrier and harbor bacteria.

The hydraulic system is the powerhouse of the table, responsible for its smooth and precise movements. Regular checks are vital to ensure its optimal performance and to prevent catastrophic failures.

Fluid Level Monitoring: Periodically check the hydraulic fluid reservoir to ensure the fluid level is within the manufacturer's specified range. Low fluid levels can lead to sluggish movements and put unnecessary strain on the pump.

Leak Detection: Regularly inspect the hydraulic cylinders, hoses, and connections for any signs of fluid leaks. A small leak can indicate a failing seal, and if left unaddressed, can lead to a complete system failure. Any detected leaks should be repaired by a qualified technician immediately.

Smooth Operation: Pay attention to the table's movements. Any signs of jerky motion, hesitation, or unusual noises could indicate air in the hydraulic lines or an issue with the pump or valves. These symptoms warrant a professional inspection.

The electric components of the table, including the motor, control units, and power cords, must be regularly inspected to ensure electrical safety.

Power Cord and Plug: Check the power cord for any signs of fraying, cuts, or damage. The plug should fit securely into the outlet. A damaged cord can lead to short circuits, electric shocks, or fire hazards.

Control Unit Functionality: Test all functions on the handheld remote and foot pedals to ensure they are working correctly. Verify that the emergency stop button is fully functional and immediately halts all table movements.

Battery Backup: For tables with a battery backup, regular checks are essential to ensure the battery holds a charge. The battery should be tested periodically by unplugging the table and verifying that all functions are operational. This is crucial for maintaining safety during a power outage.

Professional Electrical Inspection: It is recommended that a qualified biomedical technician perform a comprehensive electrical safety inspection annually. This inspection should include a ground-to-chassis continuity test and a leakage current test to ensure the table meets all safety standards.

Over time, the sensors and controls that govern the table's movements can lose their calibration, leading to inaccuracies in height, tilt, or rotation.

Routine Calibration: Follow the manufacturer’s recommendations for routine calibration. This ensures that the table’s movements are precise and repeatable, which is critical for procedures that rely on specific angles and positions.

Sensor Checks: Modern tables may have position sensors that provide feedback to the control system. These sensors should be checked for cleanliness and proper function to ensure accurate positioning.

Documentation: Keep a detailed log of all maintenance activities, including cleaning schedules, system checks, and repairs. This documentation is essential for compliance with regulatory standards and provides a clear history of the table's service life, which can be valuable for future decisions on replacement or repair.

By adhering to a strict maintenance and care protocol, a facility can maximize the lifespan of its electro-hydraulic operation tables, minimize the risk of procedural delays, and, most importantly, provide a safe and reliable platform for every surgical procedure.

The field of surgical technology is in a state of constant evolution, and electro-hydraulic operation tables are at the forefront of this innovation. The next generation of tables will move beyond their traditional role as a simple positioning device to become integrated, intelligent, and highly adaptable platforms that are central to the modern digital operating room. These future trends are driven by the overarching goals of enhancing surgical precision, improving patient safety, and optimizing operational efficiency.

A major trend is the seamless integration of operation tables with surgical navigation systems. These systems use advanced imaging and tracking technology to create a real-time, three-dimensional map of the patient's anatomy, guiding the surgeon's instruments with pinpoint accuracy. Future electro-hydraulic tables will be a key component of this ecosystem. They will be able to receive data directly from navigation systems and automatically adjust the patient's position to maintain optimal alignment with the surgical field. This will eliminate the need for manual adjustments and the potential for human error, which is particularly critical in fields like neurosurgery and orthopedic surgery. The table's movements will be pre-programmed to work in concert with robotic arms and imaging equipment, creating a truly integrated surgical workflow.

While current tables are designed to be radiolucent, the next generation will offer even greater compatibility with advanced imaging modalities. This includes not only improved compatibility with traditional C-arms and fluoroscopy but also with emerging technologies like 3D imaging, intraoperative CT, and MRI. Future tables will feature floating tabletops that allow for smooth, multi-directional movement without disrupting the patient, enabling rapid and comprehensive imaging from any angle. The materials used in the tabletop and base will be specifically chosen to minimize image artifacts, ensuring that surgeons have a crystal-clear view of the patient’s internal anatomy. This enhanced imaging compatibility is crucial for the success of minimally invasive and image-guided surgical procedures.

Ergonomics has become a central focus in surgical table design, and this trend will only accelerate. Future tables will be designed not just for patient comfort but also to minimize the physical strain on the entire surgical team. This will involve more intuitive control systems, such as voice-activated commands or gesture-based controls, that allow surgeons to make adjustments without breaking their focus or sterile field. The tables will feature a wider range of height and tilt adjustments to accommodate surgeons of different statures and preferences, reducing the risk of musculoskeletal injuries during long procedures. The design of the table's base will also evolve to provide maximum leg and foot space for the surgical team, further improving comfort and mobility within the operating room.

The rise of the Internet of Medical Things (IoMT) will transform surgical tables into "smart tables." These tables will be equipped with a network of sensors to collect a wealth of real-time data. This includes patient pressure mapping to prevent pressure sores, as well as data on table movements, tilt angles, and usage patterns. This data will be analyzed to provide valuable insights for optimizing surgical workflow, improving patient positioning protocols, and even predictive maintenance. For example, a smart table could alert a technician to a potential hydraulic leak before it becomes a major issue or provide data to help a hospital understand how to better utilize its tables. Some tables are already being developed to use RFID technology to track surgical instruments and sponges in real-time, ensuring a complete count at the end of a procedure and preventing instruments from being left inside a patient—a significant patient safety concern.